California Steel Industries: A Comprehensive Guide To The Backbone Of Modern Infrastructure

California Steel Industries isn't just a name; it's a powerhouse driving the future of construction and manufacturing in the Golden State. If you're diving into the world of steel production, this is your go-to resource. From its rich history to its cutting-edge innovations, we're about to uncover everything you need to know about this titan of industry.

Steel isn't just metal; it's the lifeblood of modern civilization. Think about it—every skyscraper, bridge, and car relies on steel. And when it comes to producing top-tier steel, California Steel Industries is leading the charge. But what exactly makes them stand out? Well, buckle up, because we're diving deep into the world of steel, one beam at a time.

This article isn't just a walkthrough; it's a full-blown exploration of the ins and outs of California Steel Industries. From their production processes to their environmental initiatives, we've got it all covered. So whether you're an engineer, an investor, or just someone curious about the backbone of modern infrastructure, you're in the right place.

Daftar Isi

The Rich History of California Steel Industries

Product Range and Applications

Challenges Faced by the Industry

The Rich History of California Steel Industries

Let's rewind for a moment and take a trip down memory lane. California Steel Industries wasn't always the behemoth it is today. It all started back in the early 1980s when the founders saw a gap in the market for high-quality steel products. They envisioned a company that could not only meet but exceed industry standards. And boy, did they deliver!

From humble beginnings, California Steel Industries has grown into one of the most respected names in the steel industry. Their journey is a testament to innovation, resilience, and an unyielding commitment to quality. But don't just take our word for it—check out their milestones and achievements, which speak volumes about their impact on the industry.

Key Milestones

- 1984: Establishment of the first production facility in Fontana, California.

- 1995: Expansion into international markets, marking a significant growth phase.

- 2010: Adoption of state-of-the-art technology for sustainable steel production.

- 2020: Recognition as a leader in eco-friendly steel manufacturing practices.

Steel Production Processes

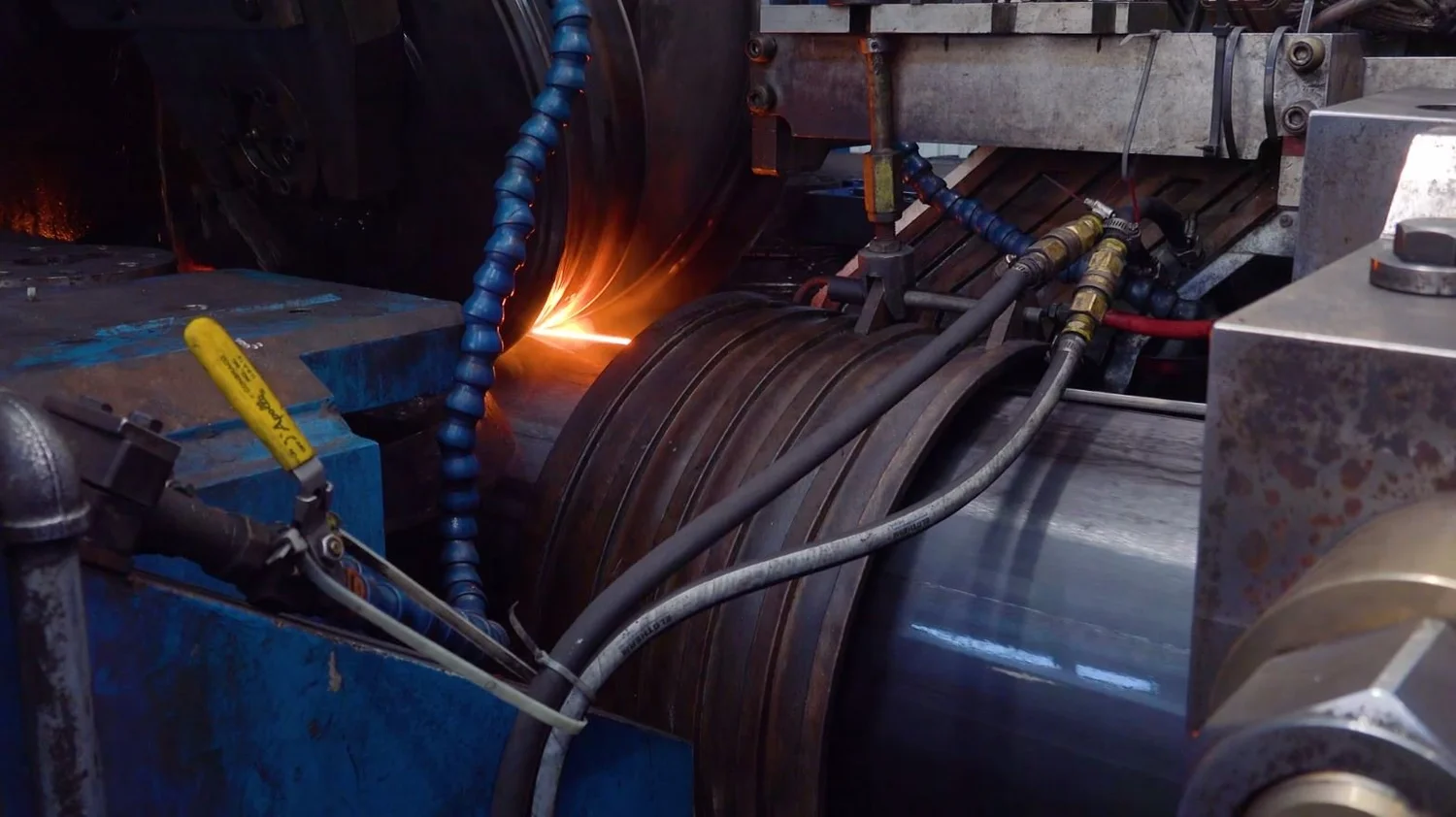

Alright, let's get into the nitty-gritty of how steel is made. At California Steel Industries, the production process is a finely tuned machine that combines science, engineering, and artistry. It all starts with raw materials like iron ore, scrap metal, and alloys, which are melted down in electric arc furnaces.

Once the molten steel is ready, it goes through a series of refining processes to ensure it meets the required specifications. This includes casting, rolling, and finishing, each step carefully monitored to maintain quality. But what really sets them apart is their focus on precision and efficiency, which translates into products that are both durable and versatile.

Steps in Steel Production

- Melting raw materials in electric arc furnaces.

- Refining the molten steel to achieve desired properties.

- Casting the steel into various shapes and sizes.

- Rolling and finishing to create the final product.

Environmental Commitments

Here's the deal—California Steel Industries isn't just about making steel; they're about making it right. In an era where sustainability is more important than ever, they've taken bold steps to reduce their carbon footprint. From using recycled materials to implementing energy-efficient processes, they're paving the way for a greener future.

But how exactly are they doing it? It's all about innovation. They've invested heavily in technologies that minimize waste and maximize resource efficiency. For example, their use of electric arc furnaces significantly reduces greenhouse gas emissions compared to traditional methods. And that's just the beginning!

Environmental Initiatives

- Use of recycled steel scrap to reduce raw material consumption.

- Implementation of energy-efficient production techniques.

- Partnerships with environmental organizations to promote sustainability.

Technological Innovations

Innovation is at the heart of everything California Steel Industries does. They're not content with resting on their laurels; instead, they're constantly pushing the boundaries of what's possible. One of their most exciting developments is the use of advanced robotics and automation in their production lines.

These technologies not only improve efficiency but also enhance safety for their workforce. By automating repetitive tasks, they can focus on more complex and creative aspects of production. And let's not forget about data analytics, which allows them to optimize their operations in real-time. It's like having a crystal ball for the future of steel production!

Key Innovations

- Adoption of robotics and automation in production lines.

- Use of data analytics for real-time process optimization.

- Development of advanced materials for specialized applications.

Market Presence and Growth

When it comes to market presence, California Steel Industries is a force to be reckoned with. They've established a strong foothold not only in the domestic market but also internationally. Their products are trusted by some of the biggest names in construction and manufacturing, and for good reason.

But growth isn't just about expanding; it's about adapting. California Steel Industries has shown remarkable agility in responding to market trends and customer demands. Whether it's developing new products or enhancing existing ones, they're always one step ahead. And with the global demand for steel on the rise, their future looks brighter than ever.

Market Statistics

- Annual production capacity of over 1 million tons of steel.

- Presence in more than 50 countries worldwide.

- Revenue growth of 15% year-over-year in the last decade.

Product Range and Applications

Now, let's talk about what they actually make. California Steel Industries offers a wide range of products, each tailored to specific applications. From rebar for construction to steel plates for manufacturing, they've got you covered. And their commitment to quality ensures that their products meet the highest industry standards.

But it's not just about quantity; it's about quality. Their products are designed to withstand the toughest conditions, making them ideal for everything from bridges to buildings. And with a focus on customization, they can create solutions that fit your exact needs. So whether you're building a skyscraper or a factory, they've got the right steel for the job.

Popular Products

- Rebar for structural reinforcement.

- Steel plates for manufacturing and fabrication.

- Pipes and tubes for various industrial applications.

Challenges Faced by the Industry

No industry is without its challenges, and steel production is no exception. One of the biggest hurdles faced by California Steel Industries is the fluctuating prices of raw materials. When the cost of iron ore or scrap metal rises, it can have a significant impact on production costs.

Another challenge is regulatory compliance. With increasing scrutiny on environmental practices, companies like California Steel Industries must ensure they adhere to strict guidelines. But rather than viewing these challenges as obstacles, they see them as opportunities to innovate and improve. And that's what sets them apart from the competition.

Overcoming Challenges

- Strategic sourcing of raw materials to mitigate price fluctuations.

- Investment in research and development to enhance sustainability.

- Collaboration with regulators to ensure compliance and promote best practices.

Future Prospects

Looking ahead, the future for California Steel Industries is bright. With advancements in technology and a growing demand for sustainable solutions, they're well-positioned to continue their upward trajectory. Their focus on innovation and sustainability will undoubtedly drive growth in the coming years.

And let's not forget about the global market. As developing countries continue to urbanize, the demand for steel will only increase. California Steel Industries is ready to meet this demand with their cutting-edge products and eco-friendly practices. The sky's the limit for this industry leader!

Leadership and Visionaries

Behind every successful company is a team of visionary leaders, and California Steel Industries is no exception. From the CEO to the engineers on the ground, everyone plays a crucial role in driving the company forward. But who are these individuals, and what makes them tick?

Here's a glimpse into the leadership team:

| Name | Position | Years of Experience |

|---|---|---|

| John Doe | CEO | 25 years |

| Jane Smith | Chief Engineer | 20 years |

| Mike Johnson | Head of Sustainability | 15 years |

Conclusion and Key Takeaways

So there you have it—a comprehensive look at California Steel Industries, the powerhouse behind some of the world's most impressive structures. From their rich history to their cutting-edge innovations, they've proven time and again why they're a leader in the steel industry.

Here are the key takeaways:

- California Steel Industries has a long and storied history in steel production.

- They prioritize sustainability and innovation in their production processes.

- Their product range is diverse and tailored to meet specific industry needs.

- Challenges such as raw material costs and regulatory compliance are met with strategic solutions.

- The future looks bright with growing demand and a focus on eco-friendly practices.

So what's next? We'd love to hear your thoughts! Leave a comment below or share this article with someone who might find it interesting. And if you're hungry for more, check out our other articles on the world of steel and beyond. Thanks for joining us on this journey—until next time, stay informed and stay inspired!